POOGI stands for Process Of Ongoing Improvement. It serves as a guidepost for on-going improvement. The process must be focus on (global) improvement. It is not a process of improving everything all the time. It is a process that is continually finding the thing that will make a dent on the global organization.

HISTORY:

It was termed by Dr.Eliyahu Goldratt, an Israel Management Guru, author of ‘The Goal’ and ‘Theory Of Constraints’. He published various books on the application of the theory of constraints to various manufacturing, engineering, and other business processes. When asked to summarise Theory Of Constraints in a single sentence,Goldratt replied with a single word “FOCUS”.

CONSTRAINTS:

Before moving forward, let us understand what Constraints are. Constraint is something that prevents the system from achieving the goal.Constraints are classified into internal and external.

Internal:When the system produces less than what the market deserves.By this the organisation should focus on Equipment,people and policy.

External:When the system produces more than what the market can bear.By this the organisation should focus on increasing its demand in the market.

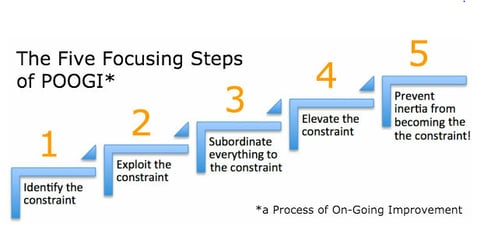

FOCUS STEPS:

On the basis of the five focus points let us see what each part does

Identify the Constraint:

Here the main motive is to figure out which process is limiting

Exploit the Constraint:

Modify or try to optimize with existing capacity

Subordinate everything to the Constraint :

Try to reduce processes to match capacity of the constraint

Elevate the Constraint:

Add capacity to the constraint process

Prevent inertia from becoming the Constraint:

Be vigilant and check if there’s a new constraint.

So how to create POOGI:

- Adopt a ”Learn from experiment” method

- Continuously improve current methods for helping individuals

- Better understand why we resist good changes or over-react and make bad changes.

Issues with POOGI:

Though POOGI can be able to remove the simplest errors it can cause issues for physically challenged as it depends on shapes and colours and follows a typical repetitive process.

References and Further Learning:

- https://www.researchgate.net/publication/322782038_THE_USE_OF_THEORY_OF_CONSTRAINT_TO_IMPROVE_ORGANIZATION_OF_WORK

- https://www.scienceofbusiness.com/a-process-of-on-going-improvement-poogi-part-29-2/

- https://www.scienceofbusiness.com/a-process-of-on-going-improvement-poogi-part-39-2/

- https://www.toc-goldratt.com/tocweekly/tag/poogi/

- https://www.tocinstitute.org/five-focusing-steps.html