Scenario: An automobile OEM in compliance with a regulatory direction abruptly discontinues one of its car models. This results in huge pileup of raw materials, work-in-process in various stages of production and finished goods that could not be used for any other cars but need to be disposed. Only the new car production is banned but the existing cars in the market or the saleable finished goods are not banned. Also being a specialised nature of industry, the parts manufactured in this company does not have an immediate fit or suitability in any other industry.

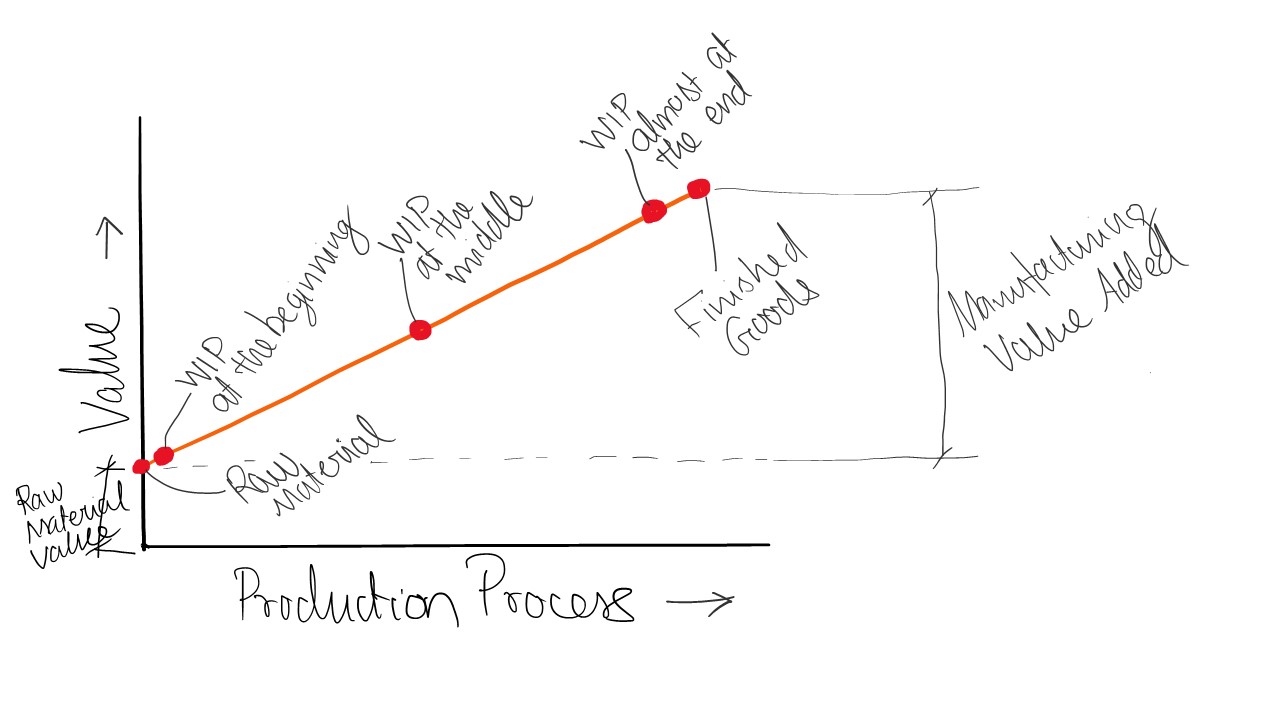

Question: Which one of the following types of inventory will fetch least value when disposed of? Here value refers to the sum of material value and manufacturing value-added.

A) The fully finished cars at the end of the production process

B) Raw materials at the beginning of the production process

C) Work-in-process roughly at the middle of the production process

D) Work-in-process either just at the beginning of the production process or just at the end of the production process

Explanation: As the cars can be sold in the market it will still fetch a good value, even though there is some reduction in value. In case of raw materials, still there is no value added on top of this, either the company can return the raw materials to the supplier or sell it to some other companies that may use this as raw material. The work-in-process at the beginning of the production process is almost equal to the raw material hence this can be sold relatively easy to sell as not much change happened in terms of form, fit and function.

The work-in-process at the end of the production process is almost equal to the finished goods. So, anyone buys this with little effort they can convert this into finished goods. But the work-in-process at the middle of the production process is neither raw material nor a finished goods would have to be sold only for the material value, but will never fetch the manufacturing value added on top of it.

Answer: Work-in-process roughly at the middle of the production process

Click here to go back to Inventory Management Body of Knowledge