IISCM has been supporting organisations across the world in developing, implementing and auditing the Supply Chain Standard Operating Procedures (SOPs) in about 25 domains. In this podcast, I would like to present why these companies are focusing on SOPs to improve their supply chains?

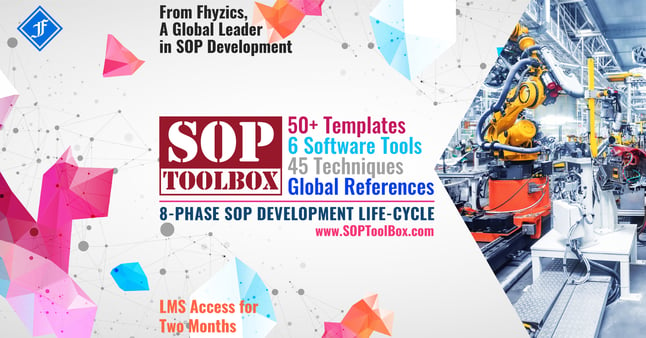

I always say, writing an SOP is somewhere between art and science. So far you may be clueless on where to start and how to progress on an SOP? This will not be the case after you diligently go through this SOP ToolBox. We have summarised all our secrets here to get you started and to deliver a stunning SOP to your management.

The primary purpose is to standardise, document and communicate the 6Qs or 6 Questions of all the activities or tasks involved in a process. The 6Qs are what, why and how of doing an activity and by whom, when and where.

The top-10 objectives of developing Standard Operating Procedures (SOPs) are

1: To capture the current state of your supply chain

2: To establish a foundation on which supply chain process improvements can be carried out

3: To create a ready reference for the employees on how to perform a process or activity

4: To set and communicate the expectations of the management to the supply chain team

5: To provide a primer to the new employees

6: To deliver consistent performance irrespective of people or geography

7: To improve the safety and security of operations in supply chain

8: To enable the organisation as a process-centric one and to attain higher level of process-maturity

9: To boost the image of your organisation in front of B2B Clients in particular

10: To show the proof of management’s intention in a court-of-law

SOP is a low-cost process improvement tool to transform your supply chain from current state to a desired future state.