The companies of this industry are mainly involved in the processes such as cutting, threading and bending the pipes (metal, plastic) and pipe fittings from purchased pipes. The companies of this industry are not directly involved in the manufacturing of the pipe. They perform all the processes on the purchased pipes only. Some of the processes which they perform on the pipes are, bending, cutting, threading, manifolds etc. This industry is dependent on the construction industry as the products are mainly used during construction work.

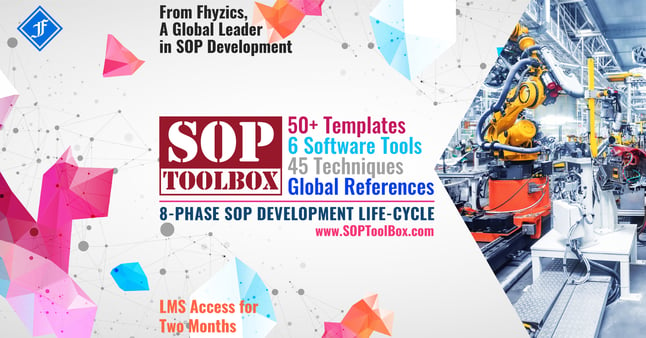

I always say, writing an SOP is somewhere between art and science. So far you may be clueless on where to start and how to progress on an SOP? This will not be the case after you diligently go through this SOP ToolBox. We have summarised all our secrets here to get you started and to deliver a stunning SOP to your management.

The steps for cutting threads on pipes are:

Step 1: Feed the pipe in machine

In the first step, the pipe will be fed in the machine for the thread cutting process. The pipe will be mounted on the head of the die and it should be in center. Alignment of pipe should be checked properly.

Step 2: Thread cutting

In this step, the machine will start cutting threads on the pipe. Hard materials tools are used to cut threads. The speed of the cutting should not be very high as it can erode the material.

Step 3: Checking the threads

The threads should be checked in between the process so that if any mistake has been done, then it can be corrected immediately. So, a worker can stop occasionally to check the threads of the pipe.

Step 4: Final inspection

A final inspection of the threads on the pipe will be done by the experts. Once the final inspection is done and the products have passed the inspection, they will be packed and shipped to the customer.

1. Standard Operating Procedures (SOP) Manual for Accounts Department

2. Standard Operating Procedures (SOP) Manual for Finance Department

3. Standard Operating Procedures (SOP) Manual for Customer Service

4. Standard Operating Procedures (SOP) Manual for CRM Department

5. Standard Operating Procedures (SOP) Manual for Credit Department

6. Standard Operating Procedures (SOP) Manual for Treasury Department

7. Standard Operating Procedures (SOP) Manual for Human Resources (HR) Department

8. Standard Operating Procedures (SOP) Manual for Training Department

9. Standard Operating Procedures (SOP) Manual for Learning & Development Department

10. Standard Operating Procedures (SOP) Manual for Administration Department

11. Standard Operating Procedures (SOP) Manual for Front Office

12. Standard Operating Procedures (SOP) Manual for House Keeping

13. Standard Operating Procedures (SOP) Manual for Safety Department

14. Standard Operating Procedures (SOP) Manual for Security Department

15. Standard Operating Procedures (SOP) Manual for Facilities Management Department

16. Standard Operating Procedures (SOP) Manual for Vigilance Department

17. Standard Operating Procedures (SOP) Manual for Legal Department

18. Standard Operating Procedures (SOP) Manual for Information Technology (IT) Department

19. Standard Operating Procedures (SOP) Manual for Sales & Marketing Department

20. Standard Operating Procedures (SOP) Manual for Design & Engineering

21. Standard Operating Procedures (SOP) Manual for Procurement Department

22. Standard Operating Procedures (SOP) Manual for Production

23. Standard Operating Procedures (SOP) Manual for SRM Department

24. Standard Operating Procedures (SOP) Manual for Supply Chain Department

25. Standard Operating Procedures (SOP) Manual for Warehouse

26. Standard Operating Procedures (SOP) Manual for New Product Development Department

27. Standard Operating Procedures (SOP) Manual for Research and Development

28. Standard Operating Procedures (SOP) Manual for Quality Department

29. Standard Operating Procedures (SOP) Manual for Calibration Department

30. Standard Operating Procedures (SOP) Manual for Maintenance Department

List of some of the machineries used in this industry are:

- Rolling machine

- Lathe machine

- CNC machine

- Cutting machine

Some of the Globally Popular Fabricated Pipe and Pipe Fitting manufacturing companies and their countries are:

Nucor Corp – Headquartered at North Carolina, USA, Freeport-McMoRan Inc – Headquartered at Arizona, USA, United States Steel Corp – Headquartered at Pennsylvania, USA, Alcoa Corp – Headquartered at Pennsylvania, USA, Steel Dynamics Inc – Headquartered at Indiana, USA, Reliance Steel and Aluminium Co – Headquartered at Los Angeles, USA

List of the International Associations connected with this industry are:

- PPFA, Plastic Pipe and Fittings Association

- TEPPFA, The European Plastic Pipe and Fittings Association

- NASPD, National Association for Steel Pipe Distributors

The famous Magazine or Journals associated with this Industry are:

- Pipe and Profile Extrusion

- World Pipelines

- Pipeline and Gas Journal

- Pipelines International

- The Tube and Pipe Journal

Standards guiding the industry

ISO sets all the standards and regulations for the fabricated pipe and pipe fitting manufacturing industries. All the companies of this industry must be adhered to the standards set by ISO. Below are some of the standards set by the ISO for manufacturing fabricated pipe and pipe fitting:

SOP Manual for Fabricated Pipe and Pipe Fitting Manufacturing

Research By : Sneha